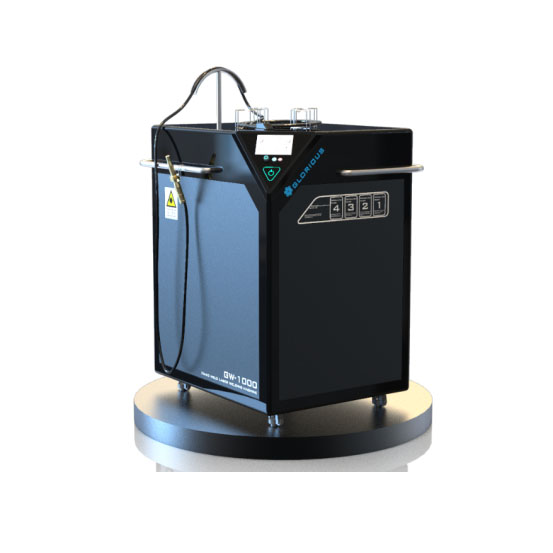

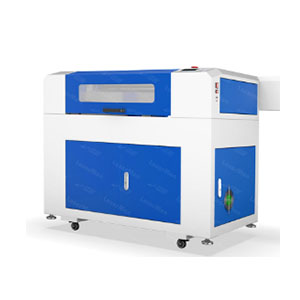

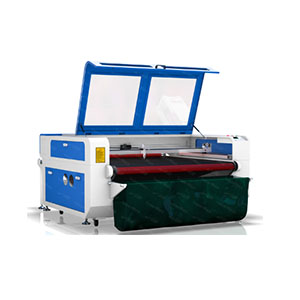

Best Price for Engraving And Cutting Machine - 300W 150W 80W 50W CO2 Laser Engraving cutting Machine 6040 – Glorious

Best Price for Engraving And Cutting Machine - 300W 150W 80W 50W CO2 Laser Engraving cutting Machine 6040 – Glorious Detail:

Causes and solutions of some minor failures of laser engraving machines

Laser engraving machine sometimes has light, sometimes no light

1. Check whether the lens is too dirty or damaged, whether the optical path is seriously deviated, clean or replace the lens, and adjust the optical path.

2. The optical path of the lens is normal, check whether the water circulation is normal, if the water is intermittent, clean or replace the water.

3. The water circulation is normal, and the water protection may be faulty. Replace the water protection.

4. If the problem persists, the motherboard, laser power supply, and laser tube may all cause this phenomenon. Replace the above accessories alternately and find the cause.

The size of the laser engraving machine’s graphic output is incorrect

Check the actual size of the graph, if there is no problem, change the machine drive subdivision, every movement, pulse.

The laser engraving machine resets abnormally

1. The direction is correct when resetting, but when it reaches the apex, the trolley and beam cannot stop (check the motherboard parameters first for the new machine, if they are correct), the motherboard and sensor are faulty, replace it.

2. The cross beam is reset normally, but the trolley does not move. It may be that the tension wheel is stuck or the motor shaft is broken. The parameter is wrong. Replace the tension wheel or small motor and modify the parameter.

The laser engraving machine stops engraving in the middle, misses engraving, and engraves randomly

1. Check the grounding condition of the machine, measure whether the ground wire meets the standard (the resistance to ground should not be greater than 5 ohms), and modify the ground wire to meet the relevant standards.

2. Check whether the computer has a screen saver or power saving mode (such as system hibernation or turning off the hard disk). For low-speed and high-speed motherboards, cancel the above settings and change to “Never”.

3. Check whether there are errors in the original graphics, such as crossover, unclosed, missing strokes, etc., and correct the errors in the graphics.

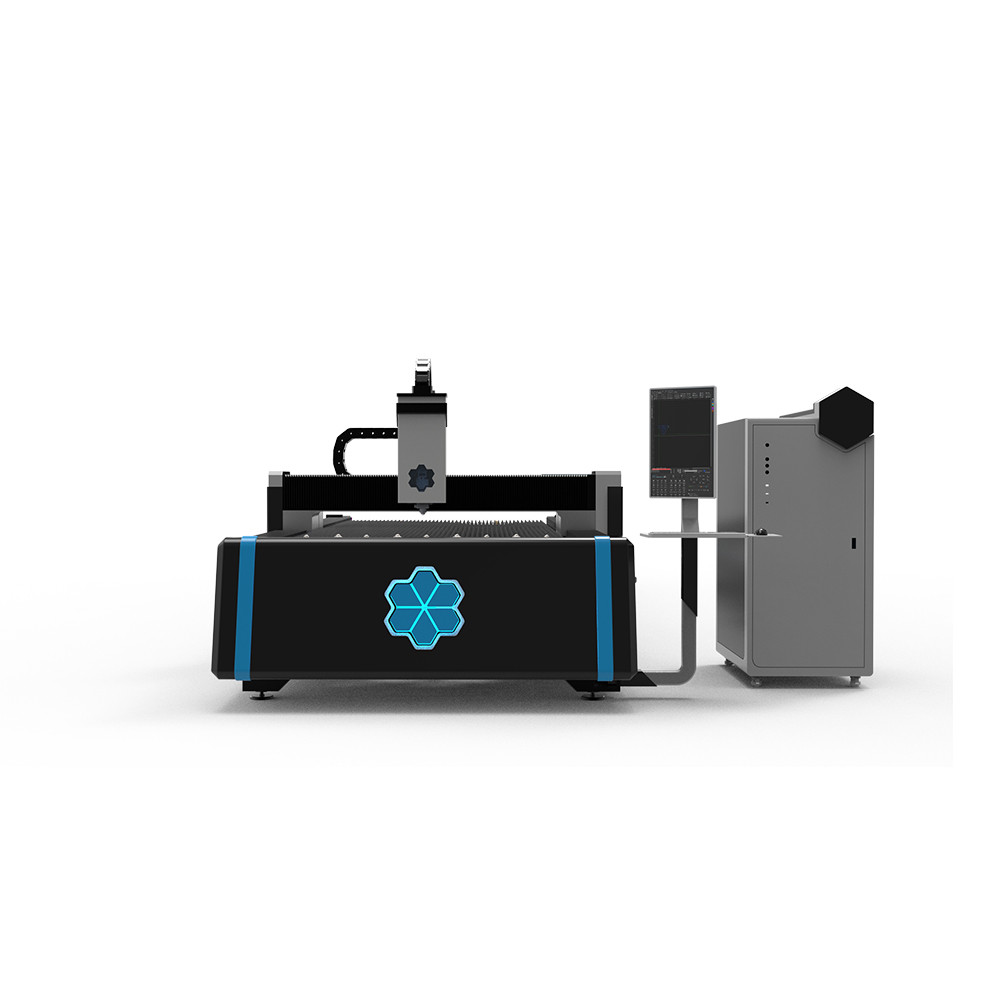

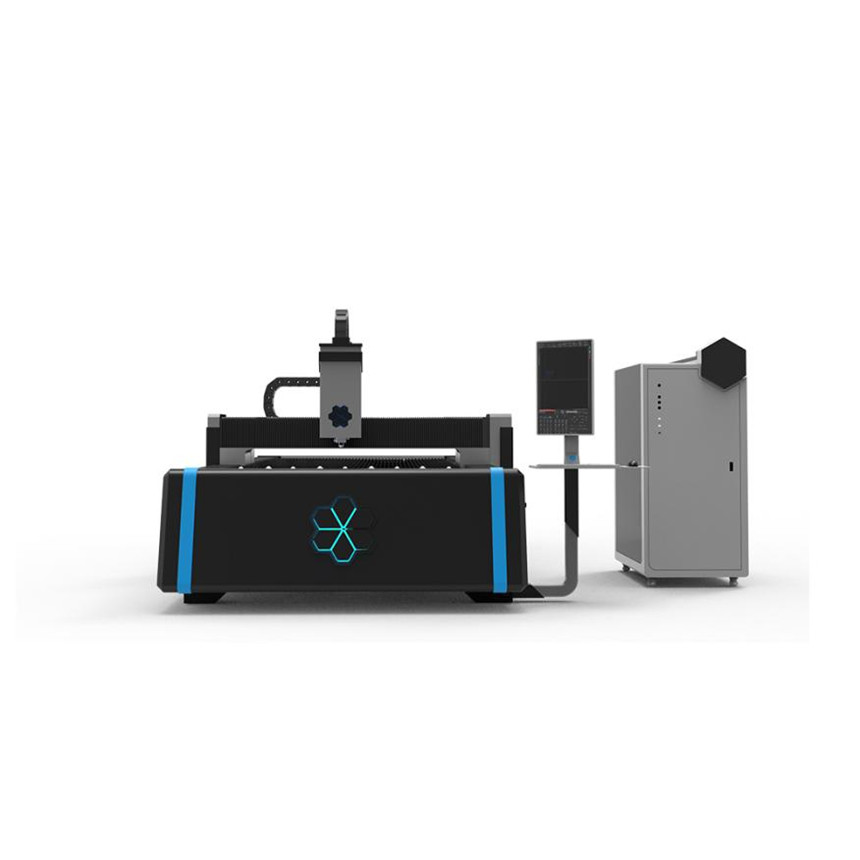

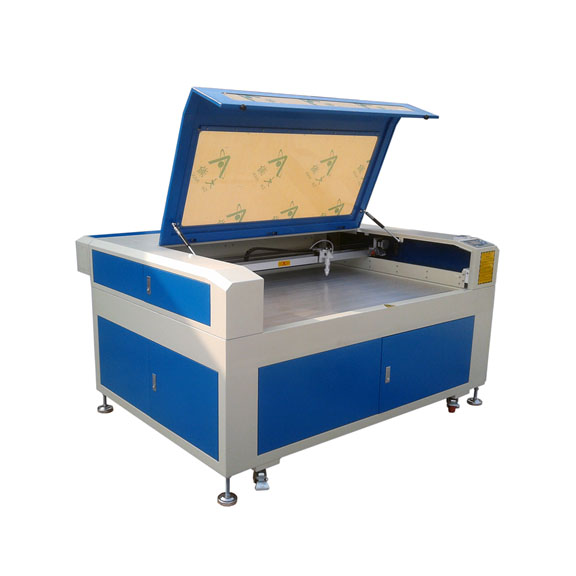

The GC series co2 cutting machine adopts the advanced control system in the industry, adds the function of continuous fast curve cutting machine, and the function of short processing path optimization, which greatly improves work efficiency. It is equipped with an advanced automatic graphic recognition system to realize fully automatic operation. The light decay compensation is automatically performed throughout the engraving process to ensure consistent engraving and cutting effects in different areas.

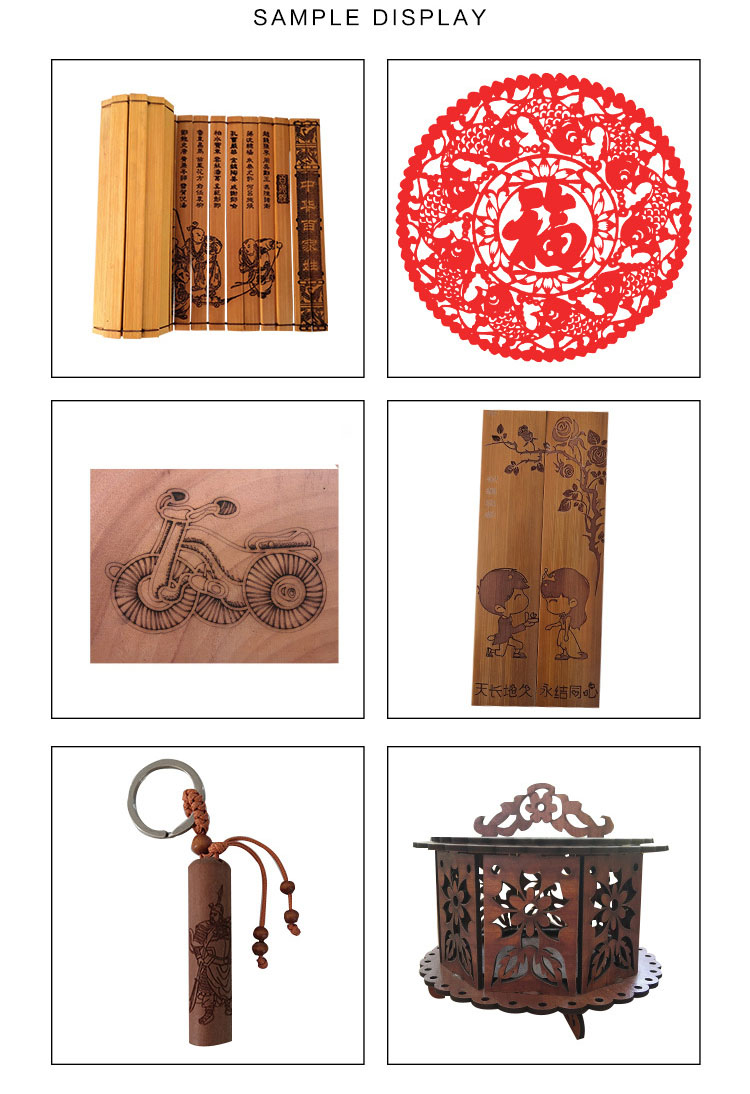

Conventional carbon dioxide cutting machine is suitable for wood products, paper, leather, cloth, plexiglass, epoxy resin, acrylic, wool, plastic, rubber, ceramic tiles, crystal, jade, bamboo products and other non-metallic materials. High-power carbon dioxide laser machines can also cut metal materials.

Ages of GC series carbon dioxide cutting machine

◎ High precision: positioning accuracy is 0.05mm, repeat positioning accuracy is 0.02mm.

◎ Narrow slit: The laser beam is focused into a very small spot to achieve a high power density at the focal point. The material is quickly heated to the degree of vaporization and evaporates to form a hole. As the beam and the material move relatively linearly, the holes continuously form slits with a very narrow width. The width of the incision is generally 0.10~0.20mm.

◎ Smooth cutting surface: There is no burr on the cutting surface.

◎ Good cutting quality: non-contact cutting, the cutting edge is little affected by heat, avoiding the collapse of the material when the material is punched and shearing, and the cutting seam generally does not require secondary processing.

◎ No damage to the workpiece: The laser cutting head will not contact the surface of the material to ensure that the workpiece will not be scratched.

◎ Can cut non-metals: such as plastic, wood, PVC, leather, textiles and organic glass.

◎ Material saving: Using computer programming, products with different shapes can be cut across the entire board to maximize the utilization of materials.

Specification of equipment

GC0403

Weight: 75kg

Device size: 1000×715×443mm

GC0604

Weight100kg

Device size:

1320×815×443mm

GC0906

Weight: 300kg

Device size:

1410×1000×1000mm

GC1006

Weight: 400kg

Device size:

1540×1230×1260

GC1209

Weight: 370kg

Device size:

1710×1300×1000mm

GC1309

Weight: 420kg

Device size:

1810×1300×1000mm

GC1409

Weight: 440kg

Device size:

1940×1420×1050mm

GC1410

Weight: 520kg

Device size:

2100×1660×1090mm

GC1610

Weight: 500kg

Device size:

2110×1400×1000mm

GC1325

Weight: 700kg

Device size:

2105×3650×1100mm

Leadshine Stepper motor

Low Vibration and low Noise forsmooth running

High torque with low generation heat

Higher Acceleration Ability, better precision & acceleration Performance

Hiwin Linear Guide Rail

Taiwan Hiwin Linear Guide Rail, long service life with high speed, high accuracy and smooth linearmotion

Reci Laser Tube

Reci brand CO2 glass tube, Long service life more than 10000H Global Quality Assurance, Free Express Water cooling system for 24H working non stop. Higher laser output power density, more concentrated light beam, uniformly light spot make high working, efficiency, high cutting speed. The focusing beam make the mark narrow line, deep scale, high resolution and more clear picture character.

Product detail pictures:

Related Product Guide:

We normally follow the basic principle Quality Initial, Prestige Supreme. We've been fully committed to offering our consumers with competitively priced good quality merchandise, prompt delivery and professional support for Best Price for Engraving And Cutting Machine - 300W 150W 80W 50W CO2 Laser Engraving cutting Machine 6040 – Glorious , The product will supply to all over the world, such as: Riyadh, Iraq, El Salvador, We win many reliable customers by rich experience, advanced equipments, skilled teams, strict quality control and best service. We can guarantee all our products. Customers' benefit and satisfaction are always our biggest goal. Please contact us. Give us a chance, give you a surprise.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.