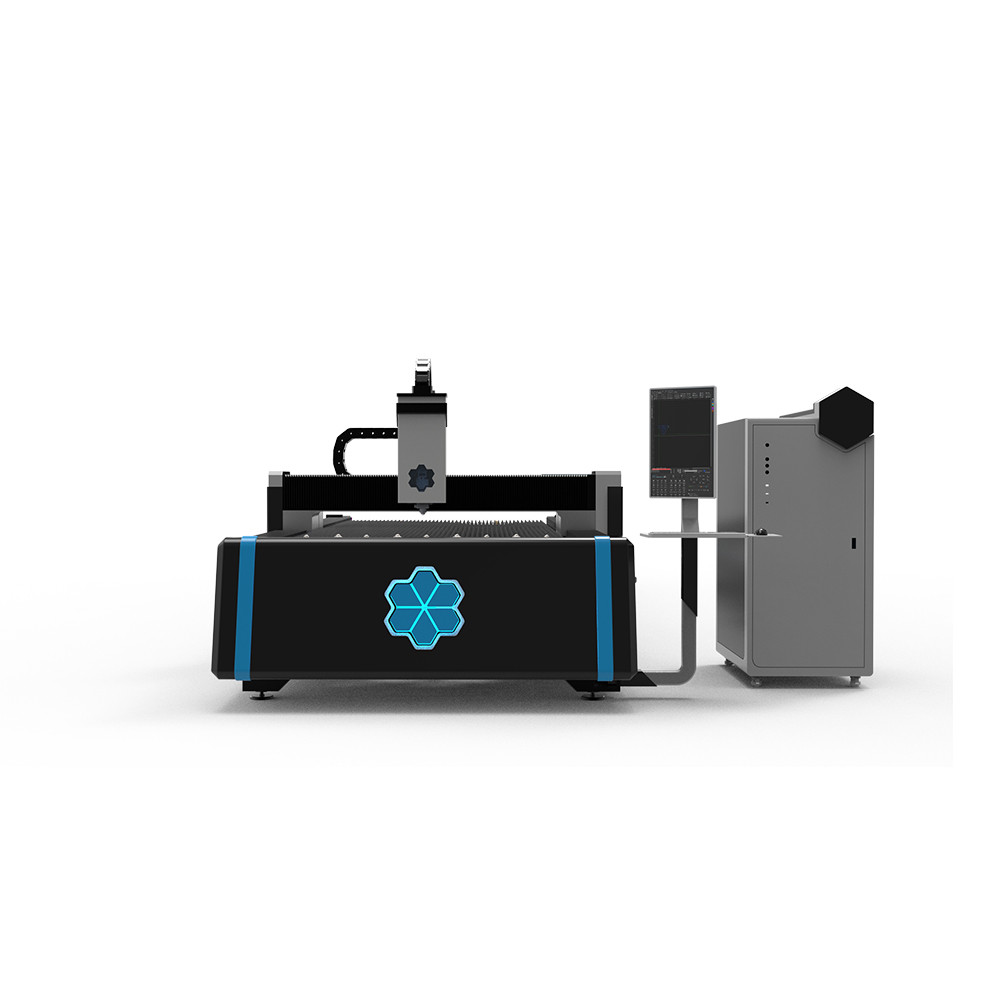

Factory wholesale Industrial Laser Etching Machine - All Cover Exchange Platform metal CNC Laser Cutting Machine – Glorious

Factory wholesale Industrial Laser Etching Machine - All Cover Exchange Platform metal CNC Laser Cutting Machine – Glorious Detail:

The difference between laser cutting machine and plasma cutting machine

1. Compared with plasma cutting, laser cutting is much more precise, the heat-affected zone is much smaller, and the slit is much smaller.

2. If you want precise cutting, small cutting seams, small heat-affected zone, and small sheet deformation, it is recommended to choose a laser cutting machine.

3. Plasma cutting uses compressed air as the working gas and high-temperature and high-speed plasma arc as the heat source to partially melt the cut metal, and at the same time blow away the melted metal with a high-speed airflow to form a cut.

4. The heat-affected zone of plasma cutting is relatively large, and the slit is relatively wide. It is not suitable for cutting thin plates because the plates will be deformed due to heat.

5. The price of laser cutting machine is a bit more expensive than plasma cutting machine.

6. I am an engineer designing laser equipment, I hope to provide help and continue to contact.

7. Laser-like plasma is actually air plasma cutting, which is a name for wanting to be exposed to laser light.

8. “Laser-like” means that the cutting effect of his plasma can be compared to that of laser.

Parameter

| Item | Subitem | GP3015 | GP4020 | GP6020 | GP6025 | GP8025 |

| Basic parameier | Working area | 3000mm*1500mm | 4000mm*2000 mm | 6100mm*2000 mm | 6100mm*2500mm | 8100mm*2500mm |

| Table load bearing | 900kg | 1600kg ≧15KW: 2200kg | 2400kg ≧15KW: 3300kg | 2950kg ≧15KW: 4200kg | 6000kg | |

| Machine overall dimensions | 9950*3050*2300mm | 12000*37 00*2300mm | 15000*4000*2300mm | 15300*4500 *2400mm | 19700*4200* 2400mm | |

| Machine weight | 8300kg | 11000kg | 17500kg | 19500kg | 22500kg | |

| Z axis travel | 315mm | 315mm | 315mm | 315mm | 120mm | |

| Fastest exchange time of platforms | 13s | 17s | 30s | 30s | 60s | |

| Operation parameier | Max. linkage speed | 140m/min | 140m/min | 140m/min | 140m/min | 140m/min |

| Max. acceleraTion | 1.5G | 1.5G | 1.5G | 1.5G | 1.5G | |

| Positioning accuracy | 0.03mm | 0.05mm | 0.05mm | 0.05mm | 0.05mm | |

| Repositioning accuracy | 0.02mm | 0.03mm | 0.03mm | 0.03mm | 0.03mm |

Product Advantage

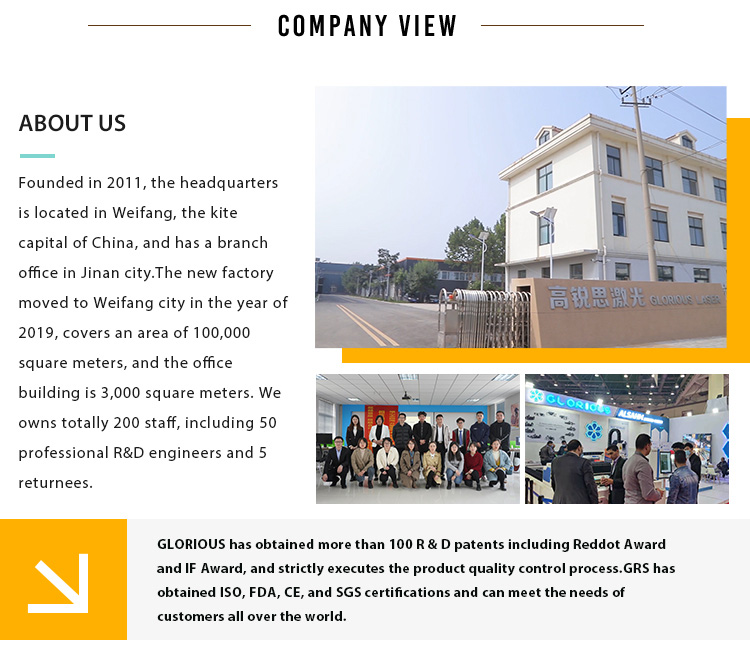

Glorious Laser provides different series of products in order to satisfy customers’ comprehensive needs. In Glorious Laser, there are totally 9 types of products with different functions from 1000 watts to 15000 watts to satisfy customers’ various needs in metal cutting under different types, shapes, sizes and maximum thicknesses.

GF Series: Sheet Metal Laser Cutting Machine GF-T Series: Dual-Use Laser Cutting Machine GE Series: Exchange Platform Sheet Metal Laser Cutting Machine GE-T Series: Exchange Platform Dual-Use Laser Cutting Machine GP Series: All Cover Exchange Platform Laser Cutting Machine GP-T Series: All Cover Exchange Platform Dual-Use Laser Cutting Machine GM Series: Precise Laser Cutting Machine GT Series: Tube Metal Laser Cutting Machine GH Series: High Power Laser Cutting Machine peration experience, effectively enhances the utilization of sheet metal and reducing waste.

1. Guarantee for 3 years.

2. Maintenance free of charge for 3 years.

3. We will provide the consumable parts at an agency price.

4. 24 hours online service, free technical support.

5. Machine has been adjusted before delivery, operation disk is included in the delivery. If there is any other questions, pls kindly tell me.

6. We have manual instruction and CD (Guiding Videos) for software Installation, operation and achine’s using and maintenance.

1. Guarantee for 3 years.

2. Maintenance free of charge for 3 years.

3. We will provide the consumable parts at an agency price.

4. 24 hours online service, free technical support.

5. Machine has been adjusted before delivery, operation disk is included in the delivery. If there is any other questions, pls kindly tell me.

6. We have manual instruction and CD (Guiding Videos) for software Installation, operation and achine’s using and maintenance.

Cast Iron Bed

(1) Clone Mold pouring, Clone production, Integrally formed, Reject splicing. (2) Durable Using flake graphite cast iron, the lowest tensile strength of which is 200MPa. High carbon content, high compressive strength and high hardness. Strong shock absorption and wear resistance. Low thermal sensitivity and bed gap sensitivity reduce the loss of equipment in using, so the machine accuracy could maintain for a long time, and no deformation in a life cycle.

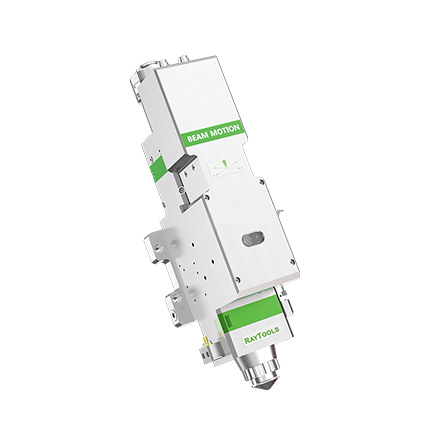

Auto Focus Iaser Head

1. Auto – focus Applicable to various focal lengths, which are controlled by machine tool control system. Focal point will be automatically adjusted in cutting process to achieve the best cutting effect of different thicknesses sheets metal.

2. Free Free your hands, focal length is controlled by operating system. We don’t need to do manual regulation, which effectively avoids errors or faults caused by manual operation.

3. Efficient When replacing different materials or different thicknesses sheet, manual focus laser head needs to adjust focal length manually, very inefficient; auto focus laser head can read system storage parameters automatically, very efficient.

4. Accuracy Increasing perforation focus length, separately setting perforation focal length and cutting focal length, enhance cutting accuracy.

5. Durable Built-in double water-cooling structures can ensure constant temperature of collimating and focusing components, avoid lenses overheating and extend service life of lenses. Increasing collimation protective lens and focus protective lens, carefully protect key components.

Cast Aluminum Crossbeam

Integral steel mold pressure casting, light, flexible and efficient. After artificial aging, solution treatment and finishing, crossbeam owns good integrity, rigidity, surface quality, toughness and ductility. Aluminum alloy’s metal characteristics of light weight and strong rigidity are helpful to high speed movement in processing, and high flexibility is beneficial to high-speed cutting of various graphics based on high accuracy. Light crossbeam can give equipment a high operation speed, improving

processing efficiency to ensure processing quality. Automobile, medical, laser additive manufacturing, microelectronics and many other applications that require advanced laser products and innovative industrial laser solutions. GW LaserTech is here to bridge the cutting-edge laser technology and the advanced manufacturing with its application expertise.

GW Laser Source

GW LaserTech, originated from the U.S., has been providing reliable and competitive industrial lasers since its inception in 2014,as well as professional laser application services and industrial laser solutions for customers around the world. GW LaserTech believes in WIIE (Win-win, Integrity, Innovation and Excellence). With the determined pursuit of cutting edge laser technology, GW LaserTech is well positioned to provide our customers the innovative industrial laser products for advanced anufacturing including aerospace.

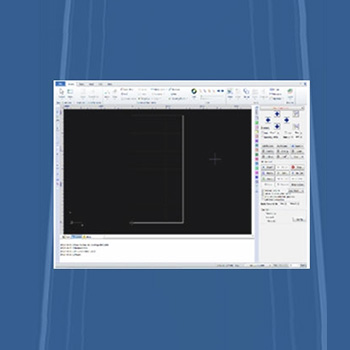

CYPCUT FS2000 Operating System

CYPCUT FS2000 operating system, perfectly combines high efficiency and simplicity with inclusiveness. The operating system can achieve intelligent layout of graphics cutting and support the import of multiple graphics, optimizing cutting orders automatically, searching edges smartly and automatic positioning. Control system adopts the best logic programming and software interaction, provides stunning operation experience, effectively enhances the utilization of sheet metal and reducing waste.

Control Panel

Elegant appearance curve. The new 24-inch touch display has a larger area and incorporates touch function for more convenience. The cooperation between the UI display and the table makes a more intuitional operation. The 10 points touch is more accurate,which improves users’experience. Simple and fast operation system, efficient and accurate cutting instructions, effectively improve the user experience.

Product detail pictures:

Related Product Guide:

Sticking for the principle of Super Quality, Satisfactory service ,We have been striving for being a superb small business partner of you for Factory wholesale Industrial Laser Etching Machine - All Cover Exchange Platform metal CNC Laser Cutting Machine – Glorious , The product will supply to all over the world, such as: Johor, Algeria, Manchester, Our expert engineering team will generally be prepared to serve you for consultation and feedback. We're able to also give you with free of charge samples to meet your requirements. Best efforts will likely be produced to provide you the best service and merchandise. When you are keen on our business and items, make sure you speak to us by sending us emails or call us quickly. In an effort to know our merchandise and company extra, you may come to our factory to view it. We'll generally welcome guests from all over the world to our business to create business relations with us. Be sure to feel cost-free to speak to us for small business and we believe we are going to share the best trading experience with all our merchants.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.