Featured Products

-

OEM China China Easy Operation 3015 1000W CNC Fiber Laser Cutting Machine with Single Platform

Instructions for use include instructions for safe operation, product overview, packaging and transportation, installation and commissioning instructions, operating instructions, equipment maintenance and troubleshooting, warranty instructions, etc.

Daily product maintenance: clean the external filter of the water cooler, replace the coolant, clean the external dust of the laser head, replace the lens, replace the nozzle, add lubricating oil, etc.

-

Supply ODM China Monthly Deals 2 Years Warranty Laser Machine High Performance Pipe and Metal Sheet Laser Cutting 1530 2030 1560 CNC Cutting Machine with Discount Price

Cutting table: It is made by welding the whole square pass, and each node adopts super thick keel to ensure long-term use, the bed does not collapse, and the structure is stable.

-

Big discounting Factory Price 3 in 1 Rust Removal 2000W 1500W 1000W CNC Stainless Steel Mini Metal Handheld Fiber Laser Welding Cutting Cleaning Machine

Using the latest generation fiber laser source and Independently developed ,XH LASER hand-held laser welding machine Filled in the blank of hand-held welding in laser equipment industry.Its advantages are simple operation, welding seam beautiful, fast welding speed and no consumables. Welding in thin stainless steel plate, iron plate, aluminum plate and other metal materials can perfectly replace the traditional argon arc welding and electric welding technology.

Handheld Fiber Laser Welding Machine

Short Description:

Using the latest generation fiber laser source and Independently developed ,XH LASER hand-held laser welding machine Filled in the blank of hand-held welding in laser equipment industry.Its advantages are simple operation, welding seam beautiful, fast welding speed and no consumables. Welding in thin stainless steel plate, iron plate, aluminum plate and other metal materials can perfectly replace the traditional argon arc welding and electric welding technology.

1. Fast welding speed, 2~10 times faster than traditional welding.

2. Easy operating need no training.

3. Welding seam beautiful smooth and beautiful, don’t need polish, save your time.

4. No deformation or welding scar, firm welding of the work piece.

5. Laser welding has less consumables and long service life.

6. Safer, more environmentally friendly.

Technical Parameters

Laser Power

1000W

1500W

2000W

Laser Source

Raycus & MAX

Welding Head

CHAOQIANG&Au3Tech

Control system

CHAOQIANG&Au3Tech

Water chiller

HANLI/S&A

Length of fiber cable

10m

Dimensions

1550X800X1350MM

Weigh

260Kg

Power Requirements

220V 1 PHASE 60HZ

Working Humidity

≤70%

Working temperature

5-45°

Welding Depth

Laser Power

1000W

1500W

2000W

Stainless steel

Max welding depth 3mm

Max welding depth 4mm

Max welding depth 6mm

Aluminum

Max welding depth 2mm

Max welding depth 3mm

Max welding depth 4mm

Mild steel

Max welding depth 3mm

Max welding depth 4mm

Max welding depth 6mm

Main Configures

Laser Source – MAX&Raycus

Stable quality and high performance, with High photoelectric conversion rate

S&A/Hanli Water chiller – S&A

Accuracy of temperature control: ±1.5℃

φ12mm Quick connector,φ6mm Quick connectorAutomatic Wire Feeding – CQWY&Au3Tech

Stepper motor, 5 meters feeding length

Wire diameter 0.8mm, 1.0mm

feeding speed 0-80mm/minWelding Head – Au3Tech

Safe and stable, easy to operate

Stable light output and beautiful weldingLCD Operator Board – CQWY

Convenient touch screen operation

Stable control system, supports multiple languages

Various Welding Nozzle

The machine is equipped with various types of nozzles to meet various types of welding jobs

Samples & Application

For the welding of thin stainless steel, carbon steel, aluminum and other metal materials, it has the characteristics of simple operation, beautiful welding seam, fast welding speed, and no consumables. Outdoor welding is possible. The operation mode of the hand-held welding torch can realize the welding of the workpiece at any angle. Suitable for all kinds of complex welds and joints on all kinds of equipment.

-

OEM/ODM Manufacturer China 500W/1000W Optional 1530 All Cover Laser Cutter for Stainless Steel Carbon Steel Laser Beam Cutting Machine

1. The laser pipe cutting machine can cut oblique angles, and the cutting speed is fast. Ordinary automatic pipe cutting machines can not cut the angle, and the one that can cut the angle is generally a semi-automatic pipe cutting machine or a manual pipe cutting machine, which has low production efficiency.

2. The function is relatively powerful, it can cut square holes and waist-shaped holes on the round pipe, can cut various patterns on the surface of the square pipe, can cut the oblique end face at the end of the round pipe, and can hollow and punch holes. The ordinary pipe cutting machine has a single function and only has a cutting function.

-

Leading Manufacturer for China Bodor Laser Metal Sheet Fiber CNC Laser Cutting Machine Price

Cutting table: It is made by welding the whole square pass, and each node adopts super thick keel to ensure long-term use, the bed does not collapse, and the structure is stable.

-

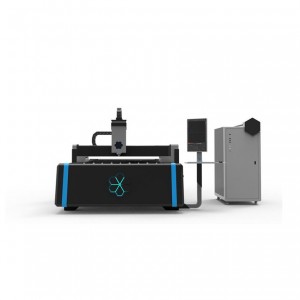

2019 wholesale price 3015 Sheet Metal Products Fiber Laser Cutter with High Laser Power 1000W 2000W 3000W 4000W 6000W Manufacturer Price

XINGHAO fiber laser cutting machine includes a cooling, lubricating and dust collection system guaranteeing durability and longevity. The strict assembly process and the world’s top brand parts ensure high cutting precision and powerful cutting ability, so as to maximize the productivity and profitability of sheet metal fabricators.

Exchange Platform – E series

Short Description:

XINGHAO fiber laser cutting machine includes a cooling, lubricating and dust collection system guaranteeing durability and longevity. The strict assembly process and the world’s top brand parts ensure high cutting precision and powerful cutting ability, so as to maximize the productivity and profitability of sheet metal fabricators.

Technical Parameters

Model

3015C

4015C

4020C

6025C

Cutting range

3050*1525mm

4000*1500mm

4000*2000mm

6000*2500mm

Laser source

Raycus & MAX & IPG

Laser power

1000-6000w

Transmission system

Gantry double drive structure

Maximum moving speed

100m/min

Maximum acceleration

1.0G

Positioning accuracy

±0.01mm/1000mm

Repeat positioning accuracy

±0.03mm/1000mm

Main Configures

IPG&MAX Laser source

IPG Photonics is a global leader of the high power fiber laser. The fiber laser manufactured by it has such advantages as high quality light beam quality andreliability, ultrahigh output power, higher electro-optical conversion efficiency,lower maintenance cost, volume with compact structure, mobility and durability,low consumption, environment friendly, etc.

Raytools Laser head

Raytools originated in Switzerland and has been specialized in the research and development of laser cutting head industry for 26 years. Its products have been sold well in more than 120 countries.

Cutting system

Cypcut is a widely used softeware of laser cutting process, with a large customer base and feedback, stable performance and comprehensive functions is a set of software for plane laser cutting, including laser cutting process processing, common layout functions and laser processing control. The main functions include graphic processing, parameter setting, user-defined cutting process editing, layout, path planning, simulation, and cutting control.

Stronger Welding Work Bed

High performance, strong stability, good integrity, rigidity and toughness;

One-piece cast aluminum beam, no rivets at both ends, more stable.Cast aluminum crossbeam

It adopts the low-pressure steel film casting process, so the crossbeam has the characteristics of high density, high rigidity and light weight, which can obtain higher dynamic response and improve processing efficiency.

Samples & Application

Sheet & Tube Laser Cutting Machine, application for process both steel sheet and tube.

Carbon and stainless steel, mild steel, soft steel, galvanized steel, coated steel, alloy, aluminum, copper, brass, titanium and more

Round, square, triangle, rectangle, oval, circular tubes and pipes.One machine can achieve two purposes. for users who need to cut plates and pipes, the purchase cost is greatly saved.

-

Factory made hot-sale China 1000W 1500*3000 Stainless Steel Aluminum Copper Sheet Metal Industrial Laser Equipment Metal Plate Tube Pipe Automatic CNC Fiber Laser Cutting Machine

Cutting table: It is made by welding the whole square pass, and each node adopts super thick keel to ensure long-term use, the bed does not collapse, and the structure is stable.

-

Personlized Products China CNC Fiber Laser Cutting Machine 2000W Ipg Raycus Laser Cutter for Metal Engraving Stainless Steel, Carbon Steel, Aluminum Cutting

1. The laser pipe cutting machine can cut oblique angles, and the cutting speed is fast. Ordinary automatic pipe cutting machines can not cut the angle, and the one that can cut the angle is generally a semi-automatic pipe cutting machine or a manual pipe cutting machine, which has low production efficiency.

2. The function is relatively powerful, it can cut square holes and waist-shaped holes on the round pipe, can cut various patterns on the surface of the square pipe, can cut the oblique end face at the end of the round pipe, and can hollow and punch holes. The ordinary pipe cutting machine has a single function and only has a cutting function.

-

Super Lowest Price Wholesale Fiber Laser Welding Machine 1000W 1500W 2000W 3000W Laser Welding CNC Machine

Using the latest generation fiber laser source and Independently developed ,XH LASER hand-held laser welding machine Filled in the blank of hand-held welding in laser equipment industry.Its advantages are simple operation, welding seam beautiful, fast welding speed and no consumables. Welding in thin stainless steel plate, iron plate, aluminum plate and other metal materials can perfectly replace the traditional argon arc welding and electric welding technology.

Handheld Fiber Laser Welding Machine

Short Description:

Using the latest generation fiber laser source and Independently developed ,XH LASER hand-held laser welding machine Filled in the blank of hand-held welding in laser equipment industry.Its advantages are simple operation, welding seam beautiful, fast welding speed and no consumables. Welding in thin stainless steel plate, iron plate, aluminum plate and other metal materials can perfectly replace the traditional argon arc welding and electric welding technology.

1. Fast welding speed, 2~10 times faster than traditional welding.

2. Easy operating need no training.

3. Welding seam beautiful smooth and beautiful, don’t need polish, save your time.

4. No deformation or welding scar, firm welding of the work piece.

5. Laser welding has less consumables and long service life.

6. Safer, more environmentally friendly.

Technical Parameters

Laser Power

1000W

1500W

2000W

Laser Source

Raycus & MAX

Welding Head

CHAOQIANG&Au3Tech

Control system

CHAOQIANG&Au3Tech

Water chiller

HANLI/S&A

Length of fiber cable

10m

Dimensions

1550X800X1350MM

Weigh

260Kg

Power Requirements

220V 1 PHASE 60HZ

Working Humidity

≤70%

Working temperature

5-45°

Welding Depth

Laser Power

1000W

1500W

2000W

Stainless steel

Max welding depth 3mm

Max welding depth 4mm

Max welding depth 6mm

Aluminum

Max welding depth 2mm

Max welding depth 3mm

Max welding depth 4mm

Mild steel

Max welding depth 3mm

Max welding depth 4mm

Max welding depth 6mm

Main Configures

Laser Source – MAX&Raycus

Stable quality and high performance, with High photoelectric conversion rate

S&A/Hanli Water chiller – S&A

Accuracy of temperature control: ±1.5℃

φ12mm Quick connector,φ6mm Quick connectorAutomatic Wire Feeding – CQWY&Au3Tech

Stepper motor, 5 meters feeding length

Wire diameter 0.8mm, 1.0mm

feeding speed 0-80mm/minWelding Head – Au3Tech

Safe and stable, easy to operate

Stable light output and beautiful weldingLCD Operator Board – CQWY

Convenient touch screen operation

Stable control system, supports multiple languages

Various Welding Nozzle

The machine is equipped with various types of nozzles to meet various types of welding jobs

Samples & Application

For the welding of thin stainless steel, carbon steel, aluminum and other metal materials, it has the characteristics of simple operation, beautiful welding seam, fast welding speed, and no consumables. Outdoor welding is possible. The operation mode of the hand-held welding torch can realize the welding of the workpiece at any angle. Suitable for all kinds of complex welds and joints on all kinds of equipment.

-

2022 China New Design China Wholsale Gold Silver Sheet Tube Fiber Laser Cutting Machine Copper Brass Small CNC Bronze Metal Fibre Cutter Robot Tube Price 1000W 2000W 3000W

1. The laser pipe cutting machine can cut oblique angles, and the cutting speed is fast. Ordinary automatic pipe cutting machines can not cut the angle, and the one that can cut the angle is generally a semi-automatic pipe cutting machine or a manual pipe cutting machine, which has low production efficiency.

2. The function is relatively powerful, it can cut square holes and waist-shaped holes on the round pipe, can cut various patterns on the surface of the square pipe, can cut the oblique end face at the end of the round pipe, and can hollow and punch holes. The ordinary pipe cutting machine has a single function and only has a cutting function.

-

Trending Products China Factory Cheapest Price Metal Steel Laser Cutting Machine 2000W CNC Fiber Laser Cutter Machine for Sheet Metal Steel Cutting

1. The laser pipe cutting machine can cut oblique angles, and the cutting speed is fast. Ordinary automatic pipe cutting machines can not cut the angle, and the one that can cut the angle is generally a semi-automatic pipe cutting machine or a manual pipe cutting machine, which has low production efficiency.

2. The function is relatively powerful, it can cut square holes and waist-shaped holes on the round pipe, can cut various patterns on the surface of the square pipe, can cut the oblique end face at the end of the round pipe, and can hollow and punch holes. The ordinary pipe cutting machine has a single function and only has a cutting function.

-

Factory wholesale Big Power Portable Copper Alloy Hand Held Fiber Laser Welding Machine with Qilin Ospri Wsx Weld Head

Using the latest generation fiber laser source and Independently developed ,XH LASER hand-held laser welding machine Filled in the blank of hand-held welding in laser equipment industry.Its advantages are simple operation, welding seam beautiful, fast welding speed and no consumables. Welding in thin stainless steel plate, iron plate, aluminum plate and other metal materials can perfectly replace the traditional argon arc welding and electric welding technology.

Handheld Fiber Laser Welding Machine

Short Description:

Using the latest generation fiber laser source and Independently developed ,XH LASER hand-held laser welding machine Filled in the blank of hand-held welding in laser equipment industry.Its advantages are simple operation, welding seam beautiful, fast welding speed and no consumables. Welding in thin stainless steel plate, iron plate, aluminum plate and other metal materials can perfectly replace the traditional argon arc welding and electric welding technology.

1. Fast welding speed, 2~10 times faster than traditional welding.

2. Easy operating need no training.

3. Welding seam beautiful smooth and beautiful, don’t need polish, save your time.

4. No deformation or welding scar, firm welding of the work piece.

5. Laser welding has less consumables and long service life.

6. Safer, more environmentally friendly.

Technical Parameters

Laser Power

1000W

1500W

2000W

Laser Source

Raycus & MAX

Welding Head

CHAOQIANG&Au3Tech

Control system

CHAOQIANG&Au3Tech

Water chiller

HANLI/S&A

Length of fiber cable

10m

Dimensions

1550X800X1350MM

Weigh

260Kg

Power Requirements

220V 1 PHASE 60HZ

Working Humidity

≤70%

Working temperature

5-45°

Welding Depth

Laser Power

1000W

1500W

2000W

Stainless steel

Max welding depth 3mm

Max welding depth 4mm

Max welding depth 6mm

Aluminum

Max welding depth 2mm

Max welding depth 3mm

Max welding depth 4mm

Mild steel

Max welding depth 3mm

Max welding depth 4mm

Max welding depth 6mm

Main Configures

Laser Source – MAX&Raycus

Stable quality and high performance, with High photoelectric conversion rate

S&A/Hanli Water chiller – S&A

Accuracy of temperature control: ±1.5℃

φ12mm Quick connector,φ6mm Quick connectorAutomatic Wire Feeding – CQWY&Au3Tech

Stepper motor, 5 meters feeding length

Wire diameter 0.8mm, 1.0mm

feeding speed 0-80mm/minWelding Head – Au3Tech

Safe and stable, easy to operate

Stable light output and beautiful weldingLCD Operator Board – CQWY

Convenient touch screen operation

Stable control system, supports multiple languages

Various Welding Nozzle

The machine is equipped with various types of nozzles to meet various types of welding jobs

Samples & Application

For the welding of thin stainless steel, carbon steel, aluminum and other metal materials, it has the characteristics of simple operation, beautiful welding seam, fast welding speed, and no consumables. Outdoor welding is possible. The operation mode of the hand-held welding torch can realize the welding of the workpiece at any angle. Suitable for all kinds of complex welds and joints on all kinds of equipment.