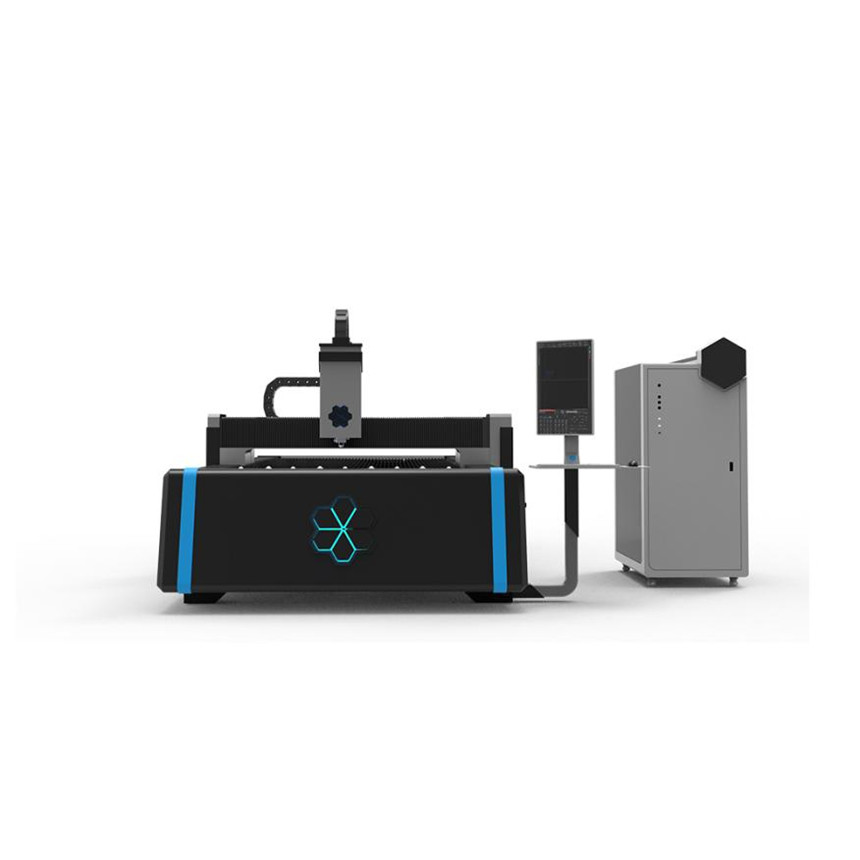

High Quality Industrial Co2 Laser Cutter – 1000W 2000W 3000W 4000W 6000W Metal Sheet Fiber Laser Cutting Machine For Metal – Glorious

High Quality Industrial Co2 Laser Cutter – 1000W 2000W 3000W 4000W 6000W Metal Sheet Fiber Laser Cutting Machine For Metal – Glorious Detail:

Parameter

| Item | Subitem | GF3015 | GF4020 | GF6020 | GF6025 |

| Basic parameier | Working area | 3000mm*1524mm | 4000mm*2000 mm | 6100mm*2000 mm | 6100mm*2500mm |

| Table load bearing | 900kg | 1600kg | 2400kg | 2950kg | |

| Machine overall dimensions | 4550*2280*200 0mm | 5500*3000*2000 | 8010*3000*2000 | 8200*3500*2000 | |

| Machine weight | 3600kg | 5600kg | 8500kg | 9000kg | |

| Z axis travel | 120mm | 120mm | 120mm | 120mm | |

| Operation parameier | Max. linkage speed | 140m/min | 140m/min | 140m/min | 140m/min |

| Max. acceleraTion | 1.5G | 1.5G | 1.5G | 1.5G | |

| Positioning accuracy | 0.03mm | 0.05mm | 0.05mm | 0.05mm | |

| Repositioning accuracy | 0.02mm | 0.03mm | 0.03mm | 0.03mm |

Cast Aluminum Crossbeam

Integral steel mold pressure casting, light, flexible and efficient. After artificial aging, solution treatment and finishing, crossbeam owns good integrity, rigidity, surface quality, toughness and ductility. Aluminum alloy’s metal characteristics of light weight and strong rigidity are helpful to high speed movement in processing, and high flexibility is beneficial to high-speed cutting of various graphics based on high accuracy. Light crossbeam can give equipment a high operation speed, improving

processing efficiency to ensure processing quality. Automobile, medical, laser additive manufacturing, microelectronics and many other applications that require advanced laser products and innovative industrial laser solutions. GW LaserTech is here to bridge the cutting-edge laser technology and the advanced manufacturing with its application expertise.

Personal Interaction

1. Who are your sales team members? What sales and sales experience do they have?

The sales team now has a total of about 8 people, with sales experience in machinery and equipment, raw materials, etc.

2. What is your company’s working hours?

Beijing time 8:30-17:30

Service

1. What are the specific contents of the instructions for use of your products? What maintenance is required for the products?

Instructions for use include instructions for safe operation, product overview, packaging and transportation, installation and commissioning instructions, operating instructions, equipment maintenance and troubleshooting, warranty instructions, etc.

Daily product maintenance: clean the external filter of the water cooler, replace the coolant, clean the external dust of the laser head, replace the lens, replace the nozzle, add lubricating oil, etc.

2. How does your company provide after-sales service for your products? Do you have an office or warehouse abroad?

After-sales service is checked online. After the problem is qualitative, the software problem is solved online, and the mechanical failure is sent by mail. Has a warehouse in Egypt.

3. What online communication tools does your company have?

WeChat, Whatsapp, etc.

4. What are your complaint hotlines and email addresses?

service@gloriouslaser.com

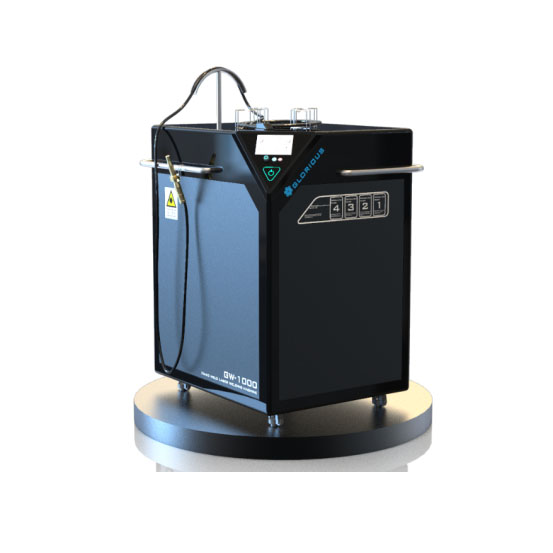

Product detail pictures:

Related Product Guide:

As a way to provide you advantage and enlarge our organization, we even have inspectors in QC Crew and guarantee you our greatest assistance and product or service for High Quality Industrial Co2 Laser Cutter – 1000W 2000W 3000W 4000W 6000W Metal Sheet Fiber Laser Cutting Machine For Metal – Glorious , The product will supply to all over the world, such as: Chile, America, Paris, We are looking forward to establishing a mutually beneficial relationship with you based on our high-quality products, reasonable prices and best service. We hope that our products will bring you a pleasant experience and carry a feeling of beauty.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.