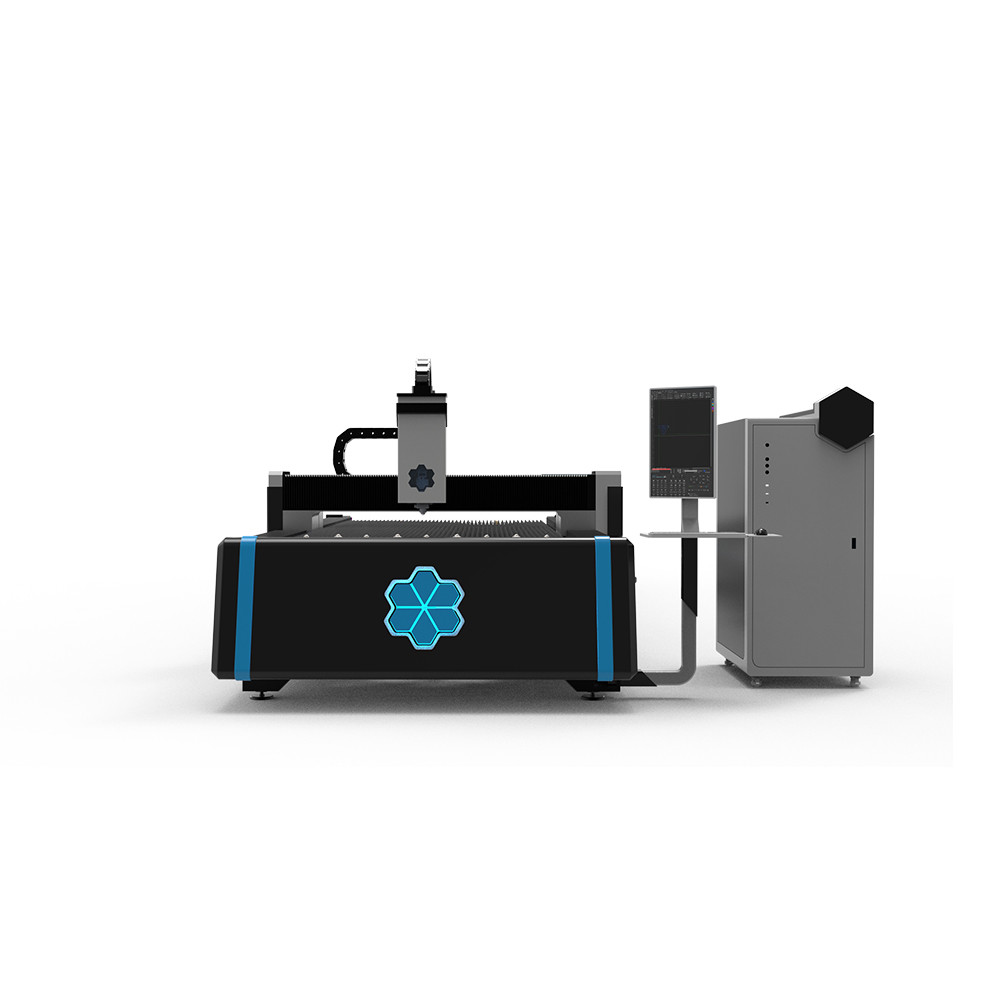

Professional China Pipe Laser Cutting Machine – 1KW 2KW 3KW 4KW Tube pipe Metal Stainless Steel Fiber Laser Cutting Machine – Glorious

Professional China Pipe Laser Cutting Machine – 1KW 2KW 3KW 4KW Tube pipe Metal Stainless Steel Fiber Laser Cutting Machine – Glorious Detail:

Why is the laser pipe cutting machine so much more expensive than the saw blade pipe cutting machine?

Why is the laser pipe cutting machine more expensive than the saw blade pipe cutting machine? Let’s take a look at the characteristics of the laser pipe cutting machine:

1. The laser pipe cutting machine can cut oblique angles, and the cutting speed is fast. Ordinary automatic pipe cutting machines can not cut the angle, and the one that can cut the angle is generally a semi-automatic pipe cutting machine or a manual pipe cutting machine, which has low production efficiency.

2. The function is relatively powerful, it can cut square holes and waist-shaped holes on the round pipe, can cut various patterns on the surface of the square pipe, can cut the oblique end face at the end of the round pipe, and can hollow and punch holes. The ordinary pipe cutting machine has a single function and only has a cutting function.

3. The laser can cut pipes with a thickness of 0.29-12MM and a diameter of 10-270MM, while ordinary pipe cutting machines are limited by saw blades and are only suitable for cutting pipes with a wall thickness of 5MM or less and a diameter of 140 or less.

4. The laser pipe cutting machine can cut special-shaped pipes, and it can cut anything that ordinary pipe cutting machines cannot.

5. The laser can cut a wider range of materials, which can cut all kinds of metal pipes, while ordinary pipe cutting machines need to choose the corresponding pipe cutting machine according to the hardness of the pipe. Not one machine can cut all metal pipes.

5. The laser cutting seam is small and there is no material loss problem.

This is the reason why the price of laser pipe cutting machine is higher than that of ordinary pipe cutting machine.

Parameter

| Item | Subitem | GT6 | GT9 |

| Basic parameier | Maximum machinable lube length | 6000mm | 9000mm |

| Maximum tube weight | 100Kg 16.7Kg/m or 150Kg 25kg/m | 10OKg 16.7Kg/m or150Kg 25kg/m | |

| Maximum blanking length | 25*φD 25 times the diameier | 25*φD 25 times the diameTer | |

| Shonesi remaining material | 200mm | 200mm | |

| Dimensions | 10000x1400x2400 mm | 15500x1400x2300mm | |

| Machine weight | 2100kg | 2900kg | |

| Operation parameter | Positioning accuracy | 0.05mm | 0.05mm |

| Repositioning accuracy | 0.03mm | 0.03mm | |

| Max. Chuck roiaxing speed | 75r/min | 75r/min | |

| X axis maximum speed | 30m/min | 30m/min | |

| Y axis maximum speed | 60m/min | 60m/min | |

| X maximum acceleration | 1G | 1G | |

| Y maximum acceleration | 1G | 1G | |

| Z axis maximum speed | ≧50m/min | ≧50m/min |

Product detail pictures:

Related Product Guide:

We emphasize progress and introduce new solutions into the market each year for Professional China Pipe Laser Cutting Machine – 1KW 2KW 3KW 4KW Tube pipe Metal Stainless Steel Fiber Laser Cutting Machine – Glorious , The product will supply to all over the world, such as: Mozambique, Chicago, Honduras, With excellent products, high quality service and sincere attitude of service, we ensure customer satisfaction and help customers create value for mutual benefit and create a win-win situation. Welcome customers all over the world to contact us or visit our company. We will satisfy you with our professional service!

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!