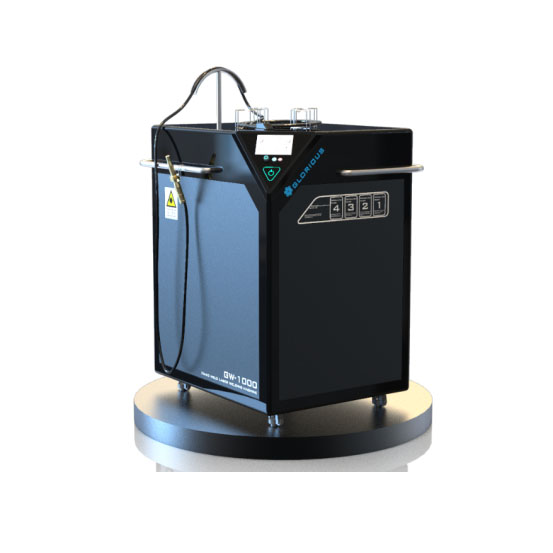

Renewable Design for Laser Welding Head - 1000W 1500W 2000W Handheld Laser Welding Machine For Metal Stainless Steel – Glorious

Renewable Design for Laser Welding Head - 1000W 1500W 2000W Handheld Laser Welding Machine For Metal Stainless Steel – Glorious Detail:

GWLS laser welding machine

Laser welding is the use of high-energy laser pulses to locally heat the material in a small area and meticulously complete the material transformation. The energy of laser radiation diffuses into the material through heat conduction at a fast rate, and the material is melted to form a specific molten pool. It is a new type of welding method, applied to the welding of precision parts and thin-walled materials, spot welding, sealing welding, butt welding, butt welding, etc., with high aspect ratio, small weld width, small heat-affected zone, and small deformation. The welding speed is fast, the welding seam is smooth, exquisite and beautiful.

Wire Feeder

Wire feeding speed: 0-80mm/min

Wire feeding length: 5 meters

Wire feeding diameter: 0.8mm, 1.0mm 1.2mm 1.6mm

Maximum diameter of wire reel: 200mm

Parameter

| Device model | GWLS-1000W | GWLS-1500W | GWLS-2000W | |||

| Maximum laser power | 1000W | 1500W | 2000W | |||

| Laser type | Fiber laser | |||||

| Laser wavelength | 1070nm±5nm | |||||

| Adjust frequency | 5000HZ | |||||

| Maximum penetration of laser welding | 2.5mm(carbon) | 3.5mm(carbon) | 4.2mm(carbon) | |||

| Fiber core diameter | 50-100um | |||||

| Fiber length | 5m(customizable) | |||||

| Maximum power of the whole machine | 4.7KW | 6.8KW | 9KW | |||

Advantages of laser welding

1. Light weight, small size, ergonomic design, comfortable grip, convenient operation and good stability.

2. The device is equipped with a ring handle to protect the device from collision and facilitate pushing and pulling. And there is a working status indicator, which can visually display the status of the equipment.

3. The welding system supports process library storage, and multiple light emission modes can be adjusted.

4. The system monitors the operating status from time to time, monitors and collects the operating status of the laser, chiller, and control panel. The safety lock touches and emits light to ensure safe use.

5. The precise positioning of the red light is convenient for observation, and the operation is simple, and the welding can be done by hand.

6. With intelligent automatic wire feeder, the control screen directly digitally sets the parameters of the wire feeder, and the operation is simple.

7. Support delivery (0.8, 1.0, 1.2, 1.6) stainless steel, carbon steel, aluminum welding wire to meet a variety of different scenarios.

8. Fully sealed structure with built-in water and air channels.

9. The control cabinet adopts an independent heat dissipation system to improve the overall operation stability of the equipment.

10. The welding seam is beautiful, fast, no welding marks, no discoloration, and no need for later polishing.

What is the difference between laser welding and argon arc welding?

Different technical principles

1. Laser welding: laser radiation heats the surface to be processed, and the surface heat diffuses to the inside through heat conduction. By controlling the laser parameters such as the width, energy, peak power and repetition frequency of the laser pulse, the workpiece is melted to form a specific molten pool.

2. Argon arc welding: On the basis of the principle of ordinary arc welding, the metal welding material is protected by argon gas, and the welding material is melted into a liquid form on the welded substrate through high current to form a molten pool, so that the welded metal and A welding technology in which the welding material achieves metallurgical bonding. Due to the continuous supply of argon gas during high-temperature fusion welding, the welding material cannot be in contact with oxygen in the air, thereby preventing the oxidation of the welding material.

Two, different application areas

1. Laser welding: laser tailored welding technology has been widely used in foreign car manufacturing; laser welding has been widely used in the electronics industry, especially in the microelectronics industry.

2. Argon arc welding: Argon arc welding is suitable for welding non-ferrous metals and alloy steels that are easy to oxidize (mainly welding of Al, Mg, Ti and their alloys and stainless steel); suitable for single-sided welding and double-sided forming, such as bottom welding Welding with pipes; argon tungsten arc welding is also suitable for thin plate welding.

Product detail pictures:

Related Product Guide:

Responsible excellent and fantastic credit rating standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of quality initial, buyer supreme for Renewable Design for Laser Welding Head - 1000W 1500W 2000W Handheld Laser Welding Machine For Metal Stainless Steel – Glorious , The product will supply to all over the world, such as: Estonia, Mombasa, Slovak Republic, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!