Wholesale Price China Flying Fiber Laser Marking Machine - 20W 30W 50W 70W 100W CNC Laser Marking Machine For Metal – Glorious

Wholesale Price China Flying Fiber Laser Marking Machine - 20W 30W 50W 70W 100W CNC Laser Marking Machine For Metal – Glorious Detail:

Four differences between laser marking machine and laser engraving machine

The following are the four differences between laser marking machine and laser engraving machine:

1. The marking depth is different: the laser marking machine only performs marking on the surface of the material, the depth is very shallow, generally the depth is less than 0.5mm, and the depth of the laser engraving machine can be marked as deep, 0.1mm to 100mm. And so on, the specific depth still depends on the material.

2. The speed is different: the engraving speed of the laser engraving machine is generally as fast as the cutting speed can reach 200mm/s, and the engraving speed is 500mm/s; the speed of the laser marking machine is generally three times the speed of the laser engraving machine. In terms of speed, the laser marking machine is significantly faster than the laser engraving machine.

3. The processing technology is different: the laser engraving machine can be equipped with an electric lifting platform and a rotating shaft, which can engrave regular or irregular objects such as cylinders, special-shaped objects, and spheres. Due to the stability control of the Q head and the optical path setting of the laser marking machine, the platform can adjust the focal length left and right up and down, so it is mostly suitable for flat engraving.

4. The choice of laser is different: the optical path system part of the laser engraving machine is composed of three reflective lenses and a focusing lens. The laser is generally a carbon dioxide glass tube. The life of the glass tube laser is generally within 2000-10000 hours. The lasers of laser marking machines are generally metal tube lasers (non-metal marking machines) and YAG solid-state lasers (metal laser marking machines), and their service life is generally more than five years. The metal tube of the laser marking machine can be inflated again and recycled. The semiconductor module can be replaced after the life of the solid-state laser is reached.

There are many types of laser marking machines in the market, such as fiber laser marking machine, CO2 laser marking machine, ultraviolet laser marking machine, etc., but their prices are also different for different configurations.

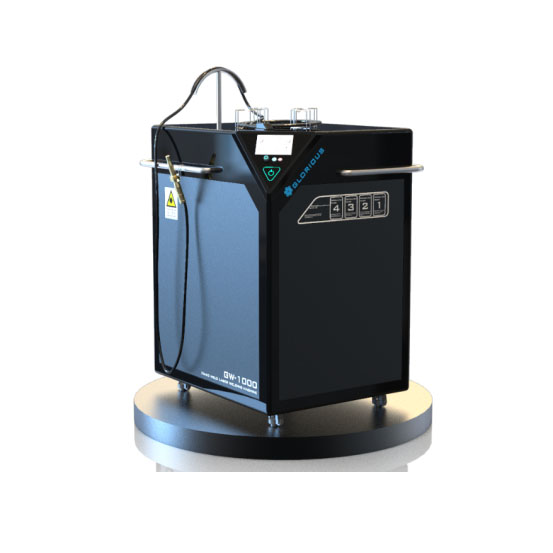

GT series optical fiber standard marking machine

Fiber laser marking mainly uses the principle of laser thermal effect, which uses the principle of burning the surface of the workpiece product with the high heat generated by the laser to form the product mark. It is mainly suitable for marking metal materials and some plastic materials. At present, the fiber laser marking machine is the most mature on the market, the longest life, the most widely used, and it is widely used in the packaging industry.

Device parameters

| The main parameters | |

| Name | GT series optical fiber standard machine |

| Laser power | 20W 30W SOW 60W 70W 80W 100W |

| Laser wavelength | 1064nm |

| Mark depth | 0-3mm (Depends on the material) |

| Line width Min | 0.01mm |

| Character Min | 0.3mm |

| Marking speed Max | 7000m m/s |

| Positioning accuracy Min | ±0.05 |

| Marking range | 110*110mm-200*200mm( custom made) |

| Cooling method | Air-cooled |

| Power Specifications | 220V/50Hz |

| Equipment size | 920*760*1100mm |

| Weight | 100 kg |

Features

1. Laser. Lasers can be selected from Ruike, Chuangxin, JPT, etc., with stable laser output and long service life.

2. Galvanometer. The galvanometer adopts Jinhaichuang or wavelength high-speed scanning galvanometer system, which is suitable for mass processing needs, with fast processing speed and good effect.

3. Field lens. Imported light-sensitive field lens, small size, suitable for harsh environments, improves the ability of the edge beam to enter the detector so that the non-uniform illumination on the photosensitive surface of the detector can be homogenized.

4. Control board. Mainly used in galvanometer laser marking machine hardware, fast data processing speed, high precision, support high-speed, high-precision non-standard functions.

Product detail pictures:

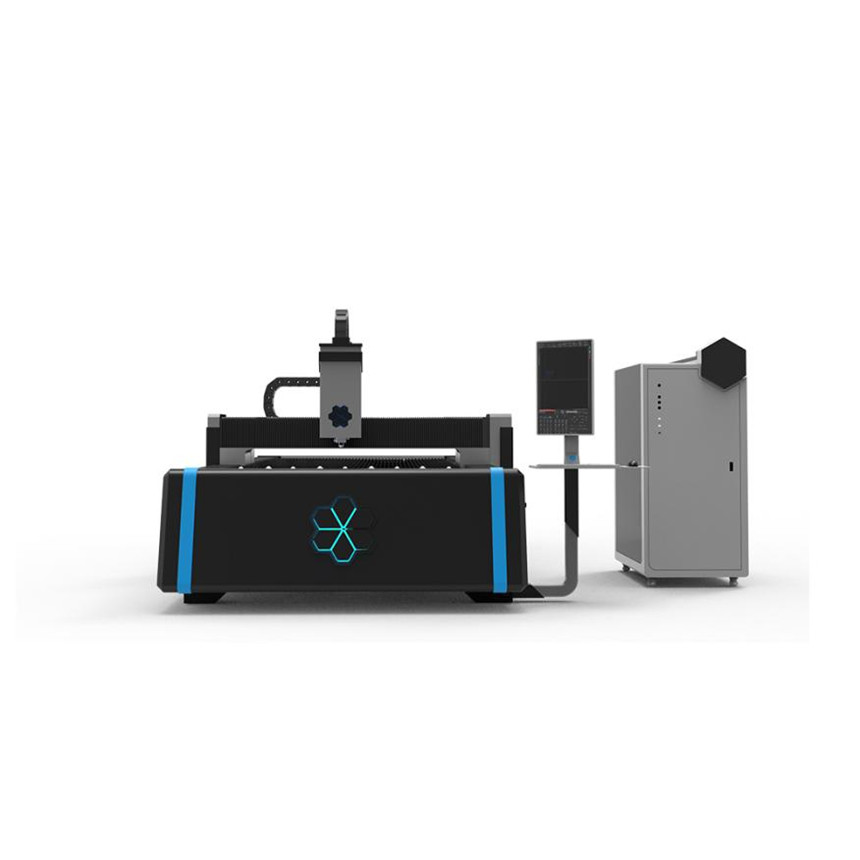

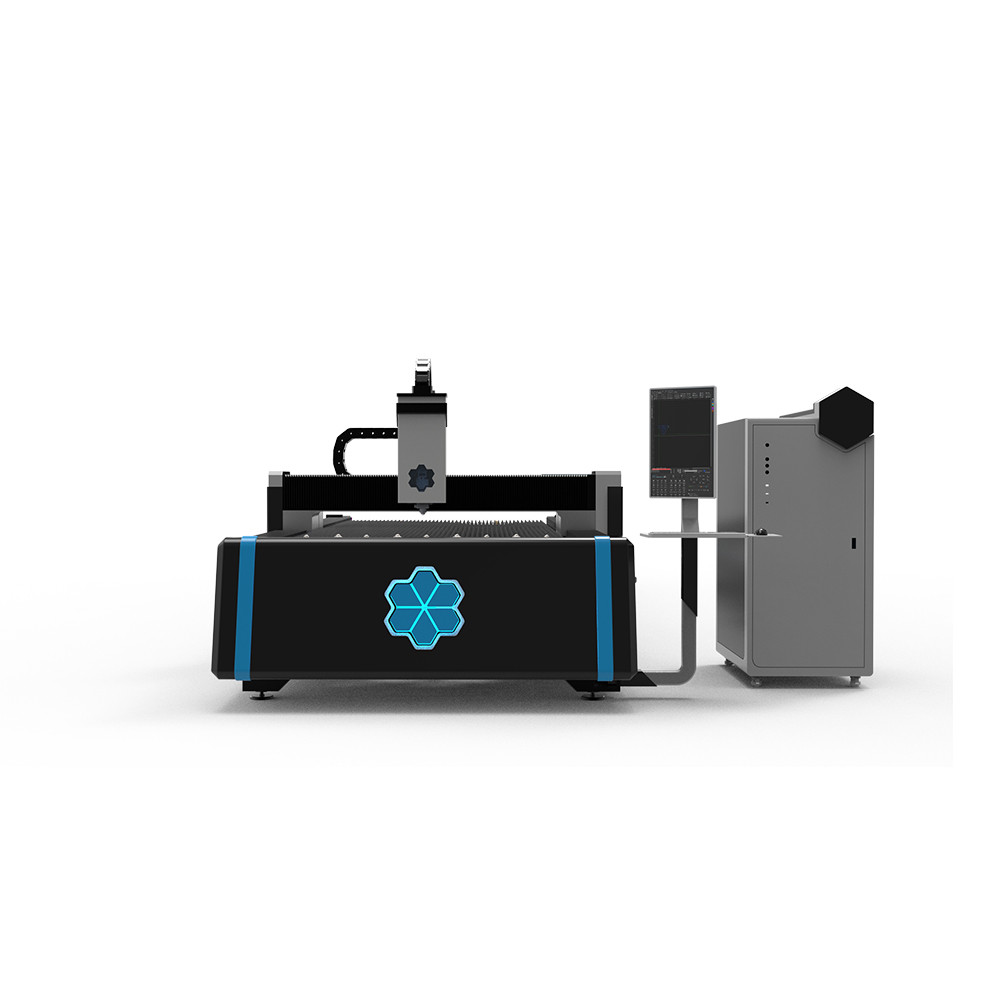

Related Product Guide:

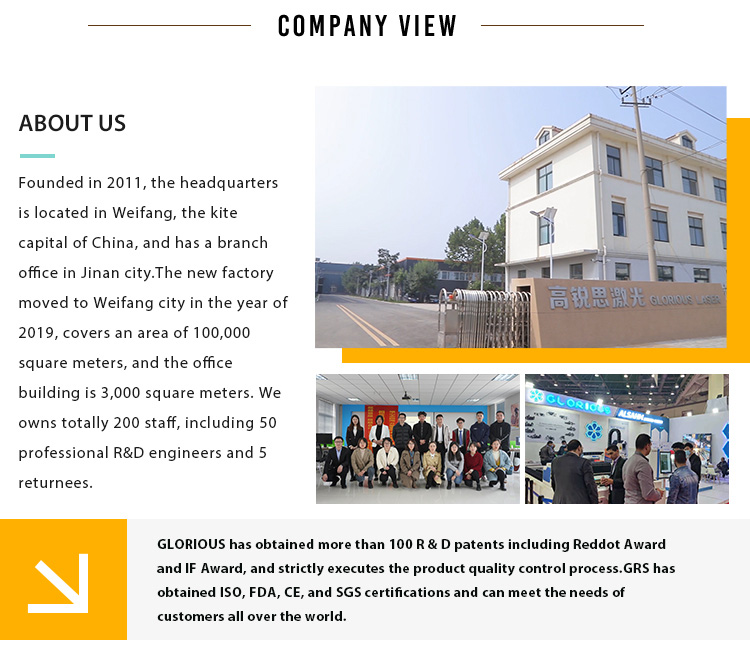

Our personnel are always in the spirit of continuous improvement and excellence, and together with the top-quality good quality solutions, favorable selling price and superior after-sales providers, we try to acquire each customer's rely on for Wholesale Price China Flying Fiber Laser Marking Machine - 20W 30W 50W 70W 100W CNC Laser Marking Machine For Metal – Glorious , The product will supply to all over the world, such as: Maldives, Jakarta, Durban, Our company always concentrate on the development of the international market. We have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.